ISO 9001:2015 certification

We produce quality!

Since Summer 2008 we are certificated according to DIN ISO 9001:2000. In summer 2018 we have reconverted successful to the new version DIN ISO 9001:2015 and correspondingly adapted our manual as well as our internal processes.

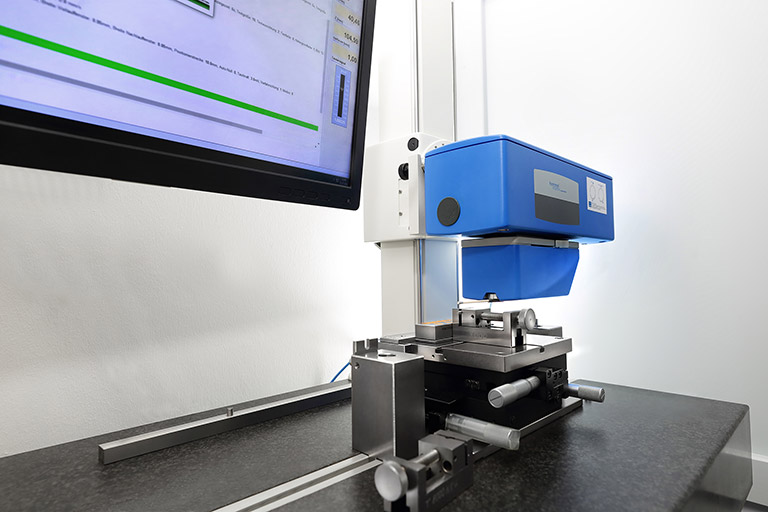

Measurement engineering

Regarding to the quality of your parts our quality department puts high demands as standard for our production. Our employees are supported due to the latest technic in the category measurement in Fabrication, inspection and control of the production batches.

From the conception of the tools within to the delivery of the final products we ensure you Quality. To ensure this, optical measurements are taken at several points during production. At central points, the contours and roughness of the products are subjected to a tactile examination.

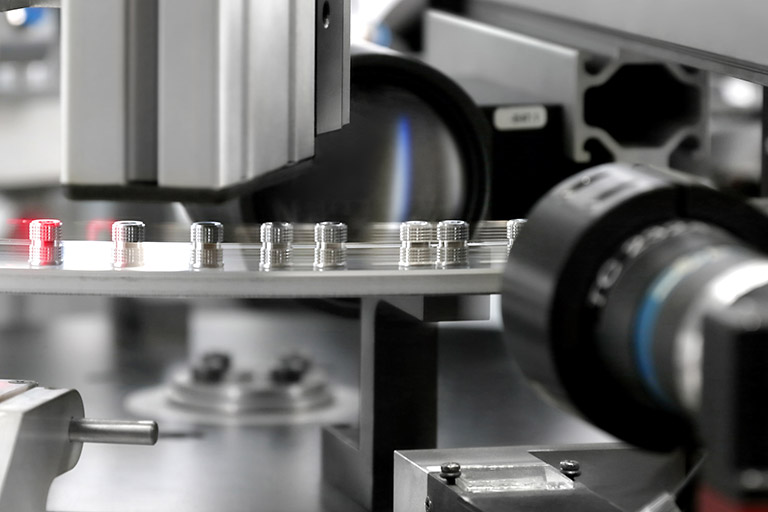

Selection / 100% control

By request we have the option to subject your parts an 100% control. According the geometry the parts may undergo a video or manuel control. Inside our companies, we have a large number of state-of-the-art selection systems at our disposal, which ensures economic selection due to our full automated video control.

Documentation and archiving

To obserev and document all quality assurance measures like SPC, FMEA, MFU we rely at the efficient and industry approved CAQ-software from ProSeS (MES-Group).

From measures report as well as EMPB within to production release process after PPAP standard, we can offer you all valid method for your start-ups. This is why we meet the high demands in the automobile industry.